12+

Years of Experienced

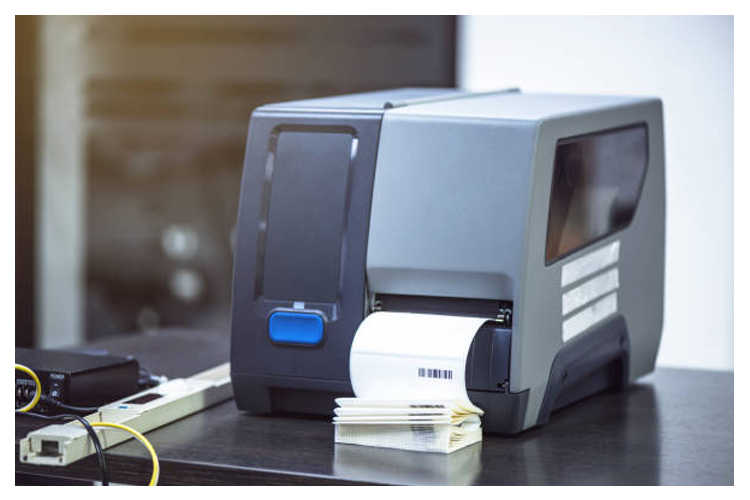

Thermal Receipt Printer Dealers in Chennai

Thermal receipt printer dealers in Chennai – Smart AIDC Systems & Solutions established in 2011 is focused on thermal and impact printing solutions. To meet our customer sales and support requirements through our sales and service centers it saves our time and money. Our inventory control maxim has a robust customer relationship, support, assembly and order fulfillment system to meet rapid customer material demands. With its ease of doing business Maxim is one of the leading small printing solution providers in Chennai serving over 500 customers in Chennai city. If you need a smooth deal with us kindly contact us : +91 97913 99552

Thermal printing (direct thermal printing) is a digital printing process which produces a printed image by passing paper with a thermo chromic coating, commonly known as thermal paper, over a print head consisting of tiny electrically heated elements.

The coating turns black in the areas where it is heated, producing an image.

Most thermal printers are monochrome (black and white) although some two-color designs exist.

Thermal transfer printing is a different method, using plain paper with a heat-sensitive ribbon instead of heat-sensitive paper, but using similar print heads.

A thermal printer typically contains at least these cost effective components:

Thermal head: Produces heat to create an image on the paper

Platen: A rubber roller which moves the paper

Spring: Applies pressure to hold the paper and print head together

- 24/7 Availability

- Trusted & Professional

- Expert Team

- Cost Effective

Thermal print head at high magnification

Thermal paper is impregnated with a solid-state mixture of a dye and a data capture suitable matrix, for example, a fluoran leuco dye and an octadecylphosphonic acid. When the matrix is heated above its melting point, the dye reacts with the acid, shifts to its colored form, and the changed form is then conserved in met stable state when the matrix solidifies back quickly enough, data capture process known as thermochromism.

This process is usually monochrome, but some two-color designs exist, which can print both black and an additional color (often red) by applying heat at two different temperatures.

In order to print, the thermal paper is inserted between the thermal head and the platen and pressed against the head. The printer sends an electric current to the heating elements of the thermal head. The heat generated activates the paper’s thermochromic layer, causing it to turn a certain color (for example, black).

Thermal print heads can have a real time resolution of up to 1,200 dots per inch. The heating elements are usually arranged as a line of small closely spaced dots.

Early formulations of the thermo-sensitive coating used in thermal paper were sensitive to incidental heat, abrasion, friction (which can cause heat, thus darkening the paper), light (which can fade printed images), and water. Later thermal coating formulations are far more stable; in practice, thermally printed text should remain legible for at least 50 days.

These all are the Thermal receipt printer types

- Barcode printer

- Dye-sublimation printer

- Line matrix printer

- Line printer

- Label printer

- Label printer applicator

- Light scribe

- Thermo graphic printing

Also sometimes called receipt printing paper, thermal paper is a kind of specialty paper that changes color when it’s exposed to heat, which means it does not require traditional ink. Thermal paper is manufactured through the application of specially designed heat-sensitive chemical materials to a paper base.